Mechanical behavior and modeling of grinding force: A

2023年9月29日 The grinding mechanism is the foundation for understanding and mastering grinding processing, providing a theoretical basis for optimizing the grinding

Grinding Processes - SpringerLink

Although grinding is traditionally regarded as a final machining process in the production of components requiring smooth surfaces and fine tolerances, much more abrasive is

Towards understanding the machining process in grinding of

2024年9月1日 To gain a thorough understanding of CMCs' grinding performance, this paper discusses in detail the removal behavior under the action of abrasive grain,

(PDF) A comprehensive review on the grinding process:

2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and...

Influence of Natural Aggregate Crushing Process on

2021年7月27日 The purpose of grinding is to achieve the desired grain size of mineral raw materials. The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as

Grinding and Abrasive Machining of Composite Materials

2021年6月22日 This chapter focuses on the grinding of polymer matrix composites (PMCs), metal matrix composites (MMCs), and ceramic matrix composites (CMCs) and

High-Speed Grinding of Advanced Ceramics and Combination

2019年4月15日 High-speed grinding is an important process for high-performance machining of advanced materials due to its capability for high-efficiency and excellent

Advances in Materials Processing - Recent Trends and

2 天之前 This book discusses advances in materials processing, especially recent trends and applications in welding, grinding, and surface treatment processes. A description of

Towards High Productivity in Precision Grinding - MDPI

In a narrow context, grinding is the removal of material using a high speed abrasive. In a wider context abrasive technology includes material removal using low speed abrasive. Innovations that allow high speed processes

Towards understanding the machining process in grinding of

2024年9月1日 To gain a thorough understanding of CMCs' grinding performance, this paper discusses in detail the removal behavior under the action of abrasive grain,

(PDF) A comprehensive review on the grinding process:

2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and...

Grinding Processes SpringerLink

Although grinding is traditionally regarded as a final machining process in the production of components requiring smooth surfaces and fine tolerances, much more abrasive is

High-Speed Grinding of Advanced Ceramics and Combination

2019年4月15日 High-speed grinding is an important process for high-performance machining of advanced materials due to its capability for high-efficiency and excellent

Grinding and Abrasive Machining of Composite Materials

2021年6月22日 This chapter focuses on the grinding of polymer matrix composites (PMCs), metal matrix composites (MMCs), and ceramic matrix composites (CMCs) and

Ultrasonic assisted grinding of ceramics ScienceDirect

1996年12月1日 PTZ-1, Pascalstra 8-9, 10587 Berlin, Germany journal of Materials Processing Technology Abstract In order to improve the machining process of

A comprehensive review on the grinding process:

2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles.

Influence of Natural Aggregate Crushing Process on

2021年7月27日 The purpose of grinding is to achieve the desired grain size of mineral raw materials. The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as

(PDF) Influence of Natural Aggregate Crushing Process

2021年7月27日 Subjecting the aggregate to the grinding process results in an improvement in the crushing strength indicator, thus obtaining better strength parameters of the products manufactured from the...

Mechanical behavior and modeling of grinding force: A

2023年9月29日 The modeling of grinding force is a complex process, the factors affecting the grinding force are the physical properties of the material, the critical depth of cut for the plastic-brittle transition of the material, the shape and size of the abrasive grits, the number of abrasive grits, the grinding parameters, the cooling and lubrication conditions, the

Grinding and Abrasive Machining of Composite Materials

2021年6月22日 2.6 Grinding Products for Composite Materials. Abrasive grains are mixed with bonding agents in order to make products for grinding composite materials. A variety of products can be used with composite materials such as grinding wheels, coated abrasives, microfinishing tape, and diamond tools for correcting the truth of wheels.

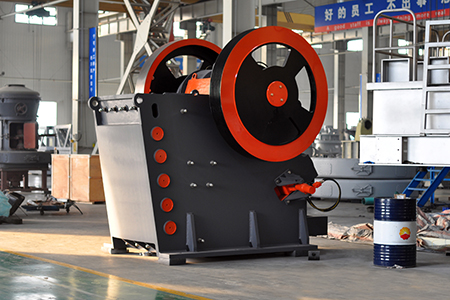

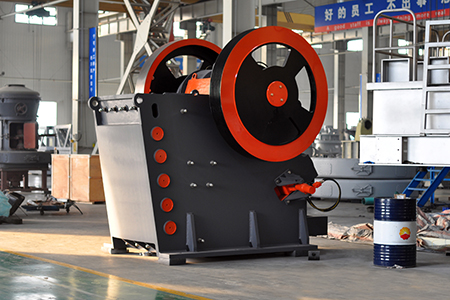

Difference between Crushing and Grinding - 911Metallurgist

2017年2月17日 When making comparisons of the efficiencies of different grinding and crushing machines it is desirable to be able to estimate the work actually done in crushing the ore from a given size of feed to a given size of product, the screen analysis of both feed and product being determined. Messrs. Klug and Taylor, in a paper on this subject,

The crushing of wheat kernels and its consequence on the grinding process

2008年7月1日 The most interesting and eco-friendly improvement strategies for the stone mill are focused on the reduction of the specific grinding energy via wheat crushing before milling [31], the rediscovery ...

Study of the surface modification resulting from an internal

1999年4月1日 1.. IntroductionA magnetic abrasive finishing process is defined as a process by which material is removed, such as in surface finishing and deburring, with the presence of a magnetic field in the machining zone [1].Since the method was originally introduced in the Soviet Union in 1938, fundamental research has been done in the

Metallurgist Mineral Processing Engineer

Aquí nos gustaría mostrarte una descripción, pero el sitio web que estás mirando no lo permite.

Improving the efficiency of the material grinding process

2020年10月27日 Creating and improving new grinding processes taking into account individual texture and physical and mechanical properties of materials is a complex mechanism and a little-researched topic.

Crushing, Grinding and Concentration of the Ore

2023年7月3日 The ores are generally contaminated with earthly or undesired materials (impurities). These are called gangue or matrix. The process of metallurgy depends upon the nature of the ore and the impurities present in it. Some common steps involved in the metallurgical operations are : 1) Crushing and grinding of the ore

The crushing of wheat kernels and its consequence on the grinding process

2008年7月1日 Crushing of the wheat kernel prior to hammer mill grinding has a significant influence on the grinding process, both on specific grinding energy and particle size distribution of the ground material, especially for soft wheat kernels. The moisture increases the grinding energy requirements, but crushing of kernels reduces it.

Crushing and grinding : the size reduction of solid materials

Semantic Scholar extracted view of "Crushing and grinding : the size reduction of solid materials" by G. C. Lowrison. Skip to search form Skip to main content Skip to account menu ... Breakage process of mineral processing comminution machines